Wilfley Pumps Save Water

Mechanical seals and compression packing waste millions of gallons of water every year.

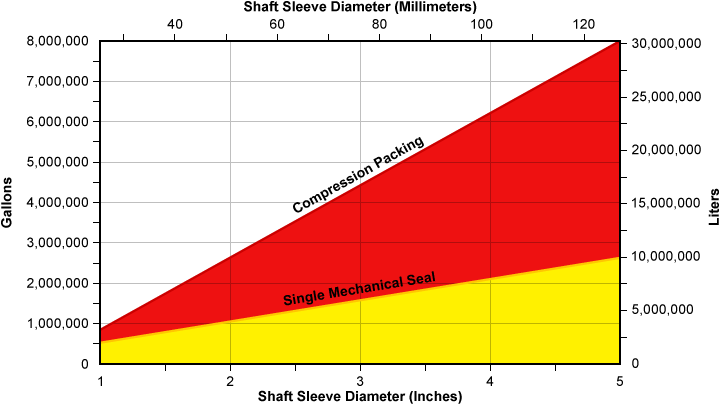

Annual Flush Water Consumption

Wilfley sealing technology provides leak free operation at all times without requiring the type of flush systems and expensive operating costs that are needed for conventional sealing systems like mechanical seals and compression packing. This might not seem very important until you look at it from a larger scale… the yearly savings can be astounding!

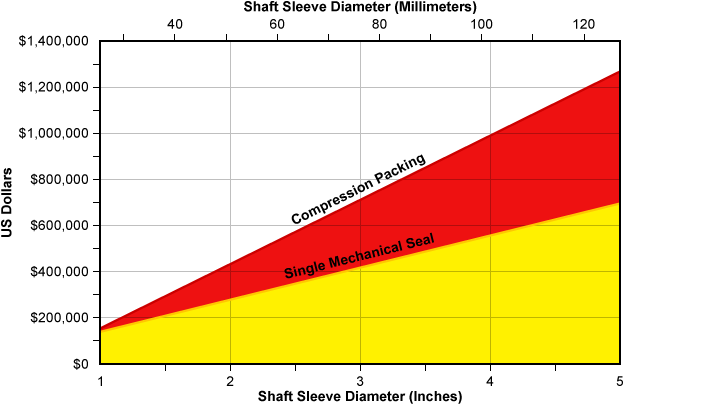

Annual Evaporating Costs

This flush-free system keeps the pumpage pure, and eliminates the need for subsequent, expensive evaporative processes downstream.

Use the calculator below to see how much water and energy your current pumps are wasting by using conventional sealing technology.

Water Usage Calculator

| Flush Flow Rate: | |||

| % | Amount Entering Process: | % | |

| Hours Per Day: | |||

| Days Per Year: | |||

| # | Quantity of Pumps: | ||

| Cost per kWh: | US Dollars | ||

| Annual Water Consumption: | |||

| Energy Cost to Remove Water: | |||

Notes on Charts:

- Charts are based on a pump running for 24 hours a day, 365 days a year. Solution contains 10-20% fine solids by weight.

- Data is based on best case scenario.

- Mechanical seal flush rate data based on 1 USGPM per inch of shaft sleeve diameter.

- Packing data is based on a “full flush” configuration with 60% of the flush water entering the process.

- Evaporating cost data based on the Fluid Sealing Association Life-Cycle Cost Estimator.

- Evaporating cost based on $0.10 per kWh.

- 1 drop of fluid = 0.0084 fl oz (0.25 ml).