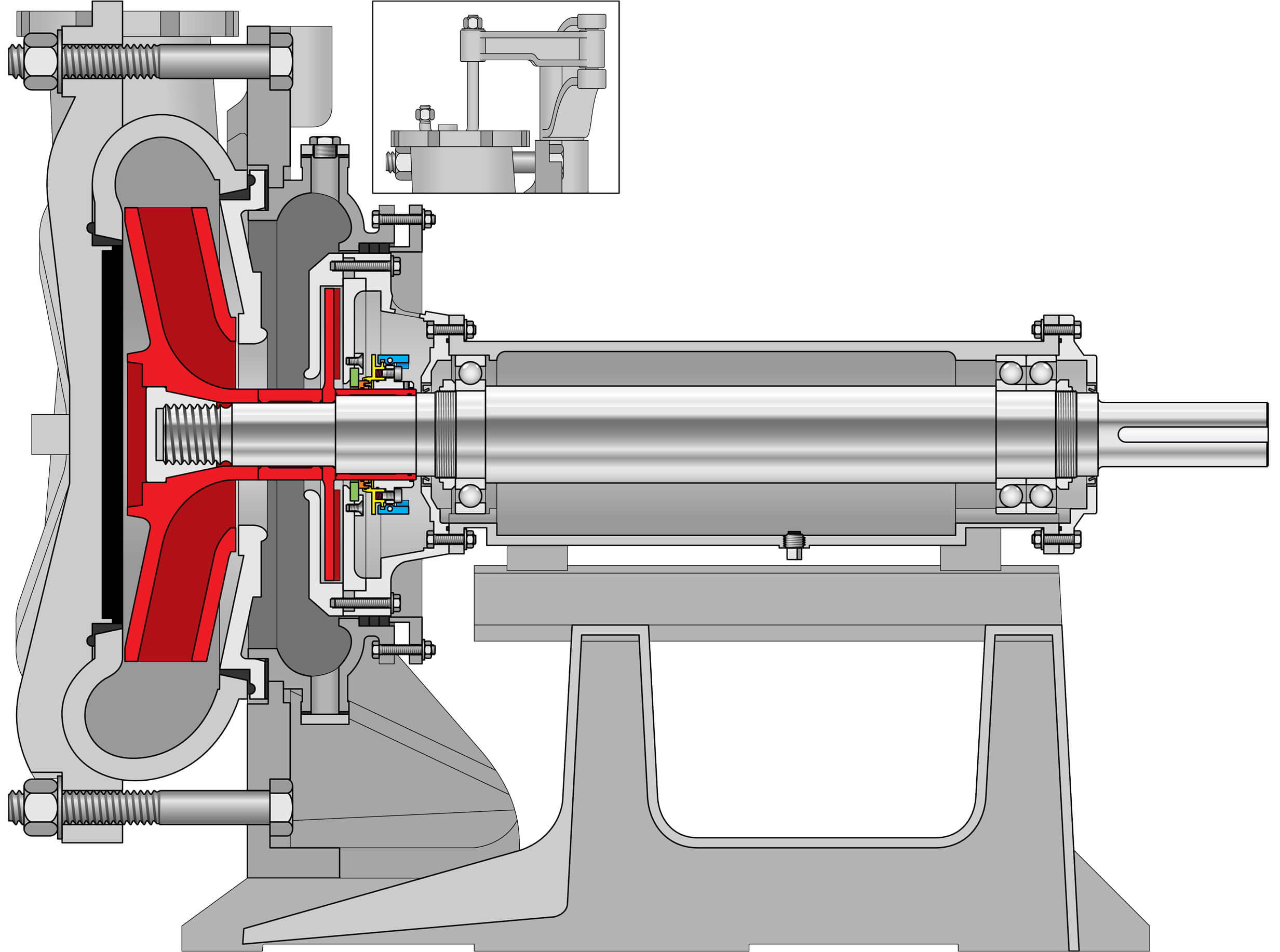

HD SLURRY PUMP

The HD is our most robust side suction slurry pump with the highest Waterless Sealing capability of the Wilfley Slurry pump range. Designed for up class 3 slurry services.

Main Benefits

- Waterless Sealing Technology

- Leakless seal operation

- Highest intake sealing capability

- High durability

- A maintenance engineer’s delight

- The case can be easily removed without disturbing suction or discharge piping

- Designed for up to class 3 slurry services

Main Applications

- Mining and mineral processing

- Wastewater

- Cement

- Thickener underflow

Key Characteristics

Capacities:

Up to 5,655 gpm (1,284 m3/hr)

Heads:

Up to 295 ft (90 m)

Max Working Pressure:

130 Psig (9 Bar)

Particle Size:

Up to 1.4 in (36 mm)

Discharge Sizes:

From 1″ (25.4 mm) to 8″ (203 mm)

Wilfley’s proprietary MAXALLOY® 5A

provides extraordinary wear performance

The expeller has been optimized

to provide the highest intake head sealing capability of the Wilfley slurry pump range

The SolidLock® static seal has been engineered

for reliable leak free sealing during start up and shut down

Various sealing options

are available to suit your specific needs

The unique side suction design

allows for exceptionally easy serviceability without ever needing to disturb the suction or discharge piping

The side suction design

optimizes the dynamic sealing capability of the expeller

Big impeller diameters and low speeds

to decrease wear

Waterless Sealing: Wilfley’s Technological Advantage

The proven engineering based on Wilfley’s dynamic waterless sealing is trusted by many companies all over the world.

Materials Options

- Maxalloy 5A

- Maxalloy 5

- Maxalloy 2

- White Iron

Seal Options

- Wilfley Waterless and Leakless Seal Technology

Solidlock

Diaphragm

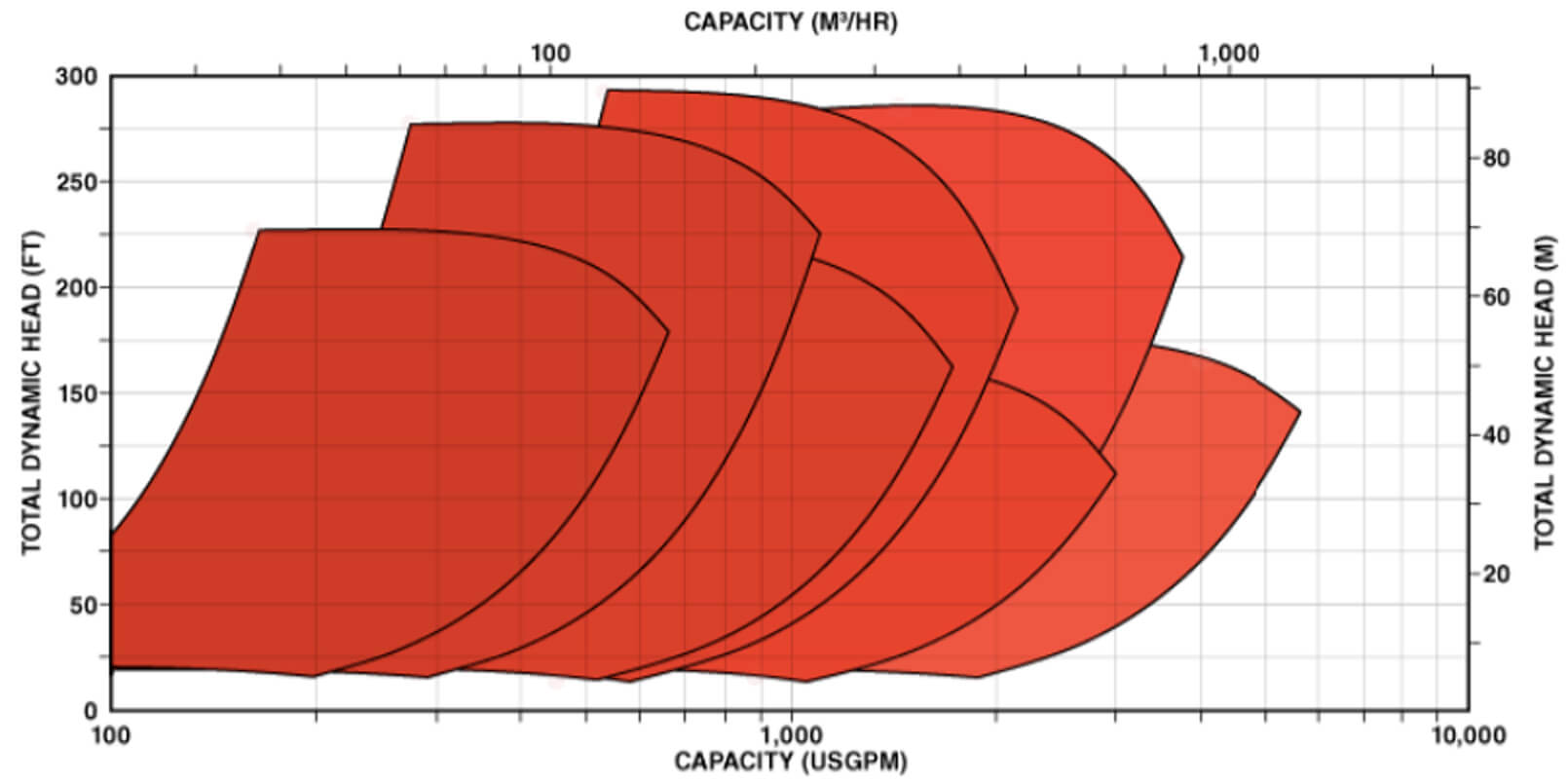

HD Pump Performance Range Capacities

Flows up to 5,655 USGPM (1,284 m3/h)

Heads up to 295 ft (90 m)

Particle size up to 1.4 in (36 mm)

HD

4x2

HD

6x3

HD

6x4

HD

8x4

HD

8x6

HD

10x6

HD

10x8

Precision Engineering, Proven Reliability

The HD pump on the right handles 65 percent of limestone solids by weight from a ball mill in a wet cement plant. The plant works 24/7, and the Wilfley pumps are vital to the success of this customer due to the no water seal consumption and the life of the Wilfley wear-resistant materials

Contact Wilfley for detailed specs, case studies, pricing and customized solutions along with answers to all your questions. We are here to help and want you to have the best options for your unique situation and operating budget.