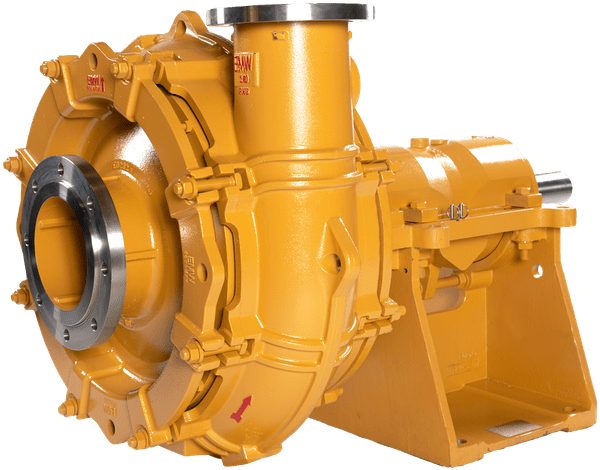

EMW PUMP

Heavy Duty Slurry Pump with abrasion resistant materials and the Wilfley Waterless Sealing Technology

The Wilfley EMW has being designed with the latest flow modeling technologies and finite element analysis to create a pump with optimum wear life. The type of design, combined with Maxalloy 5A hard iron or elastomer lining, creates the ideal slurry pump for high wear applications.

Main Benefits

- Waterless Sealing Technology

- Leakless seal operation

- High durability

- High Chrome and elastomer lined constructions

- High Efficiency, low energy consumption

- Design for up to class 4 slurry services

- Heavy-Duty bearing offer LB10 bearing life of more than 50,000 hours

Main Applications

- Mining and mineral processing

- Aggregates (sand and gravel)

- Lime Slurry

- Food Industry

- Wastewater

- Chemical slurries

Key Characteristics

Capacities:

Metal Construction: up to 17,600 gpm (4,000 m3/hr)

Elastomer Construction: up to 6,385 gpm (1,450 m3/hr)

Heads:

Metal Construction: up to 312 ft (95m)

Elastomer Construction: up to 180 ft (55m)

Max Working Pressure:

Metal Construction: up to 232 psi (16 bar)

Elastomer Construction: up to 203 psi (14 bar)

Max Temperature:

230°F (110°C)

Discharge Sizes:

Metal Construction: From 2″ (50.8 mm) to 12″ (304 mm)

Elastomer Construction: From 2″ (50.8 mm) to 8″ (203 mm)

Flanges

ASME/ANSI and ISO/DIN flanges available

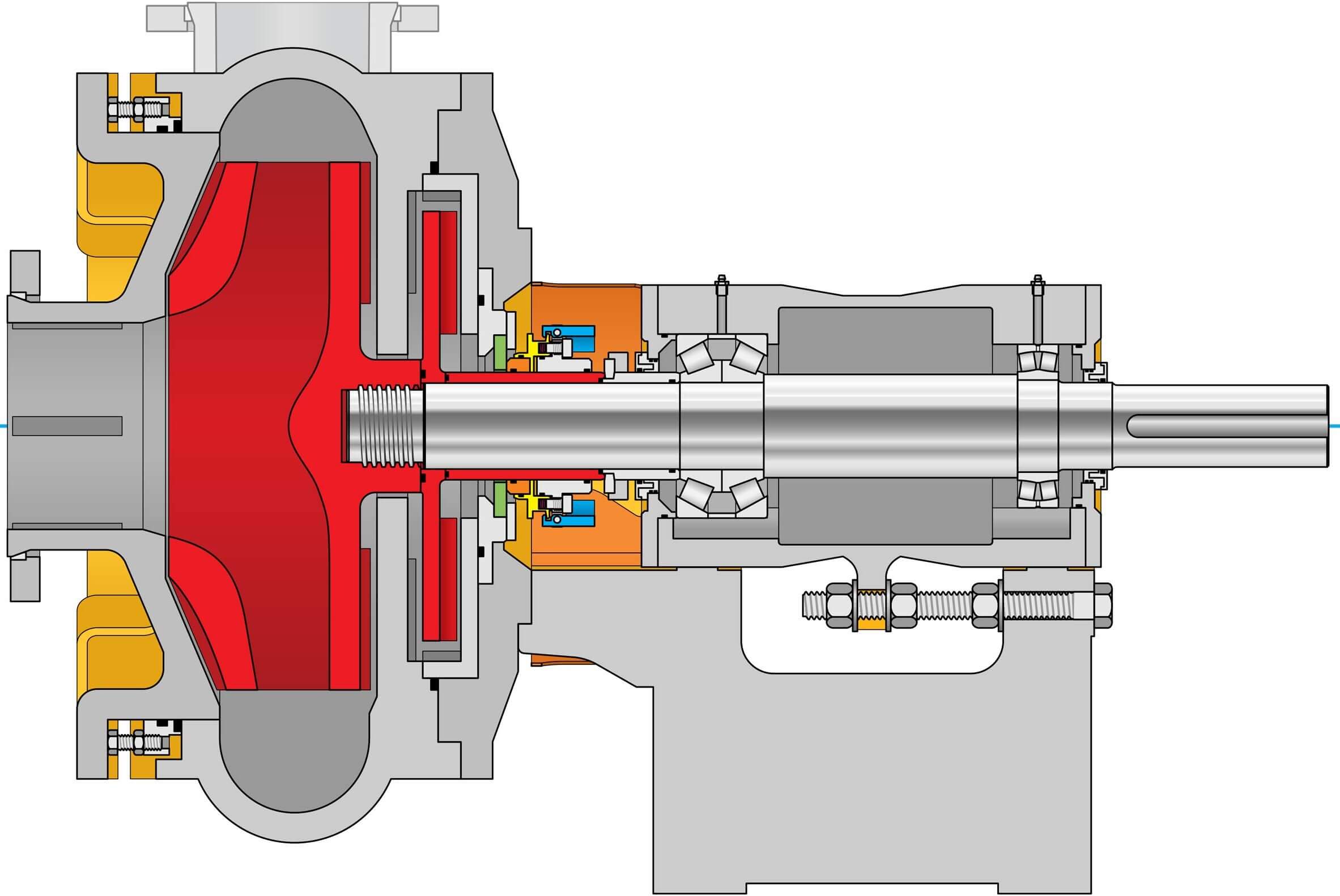

Flow straightening

vanes minimize turbulence, extend wear life, and improve performance

Adjustable suction cover

to optimize efficiency and minimize wear (larger sizes only)

Impeller vanes

Front and rear impeller vanes reduce wear

Optimized hydraulics

for high efficiency, low NPSHr, and low wear

Tangential discharge

improves efficiency and reduces wear

Static vanes

reduce wear

Optimized expeller

provides superior dynamic sealing with zero operational leakage

SolidLock® static seal

engineered for reliable sealing

Labyrinth seals

to protect internal components during wash-down cycles

Over-sized, self aligning

tapered roller bearings for trouble free operation

Easy clearance adjustment

to maintain efficiency and optimize hydraulic and/or expeller performance

Grease

lubricated power end

Waterless Sealing: Wilfley’s Technological Advantage

The Wilfley Waterless Seal Technology is a proven design combining a dynamic and static seal, that excels in demanding applications and is trusted by companies all over the world.

Materials Options

- Maxalloy 5A

- Maxalloy 5

- WCD4

- Rubber

- Neoprene

- Hypalon

Seal Options

- Wilfley Waterless and Leakless Seal Technology

- Solidlock

- Expeller with Packing

- Mechanical Seal

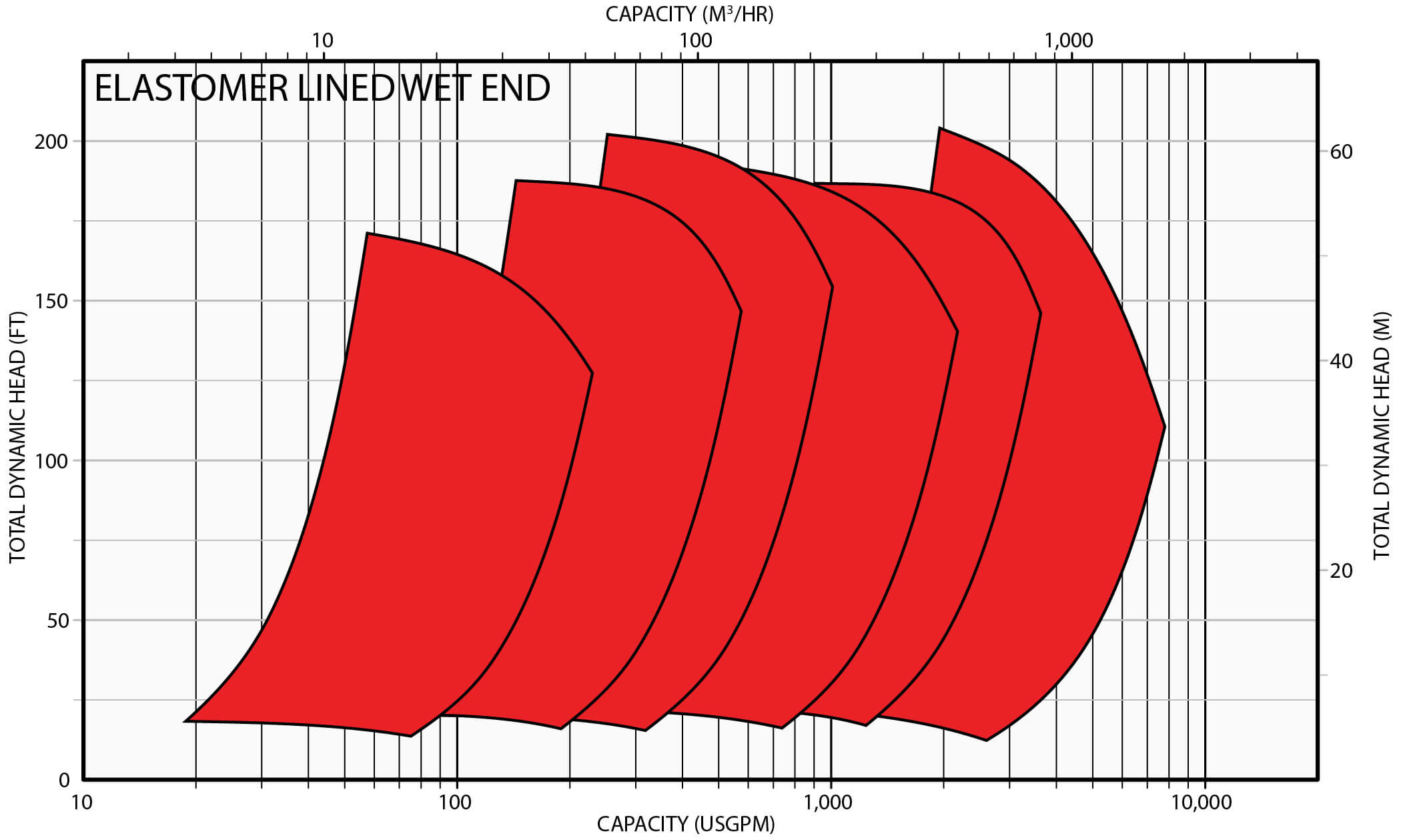

EMW Pump Performance Range Capacities

Range Capacities For Rubber

EMW 50

2x2

EMW 75

3x3

EMW 100

4x3

EMW 150

6x4

EMW 200

8x6

EMW 250

10x8

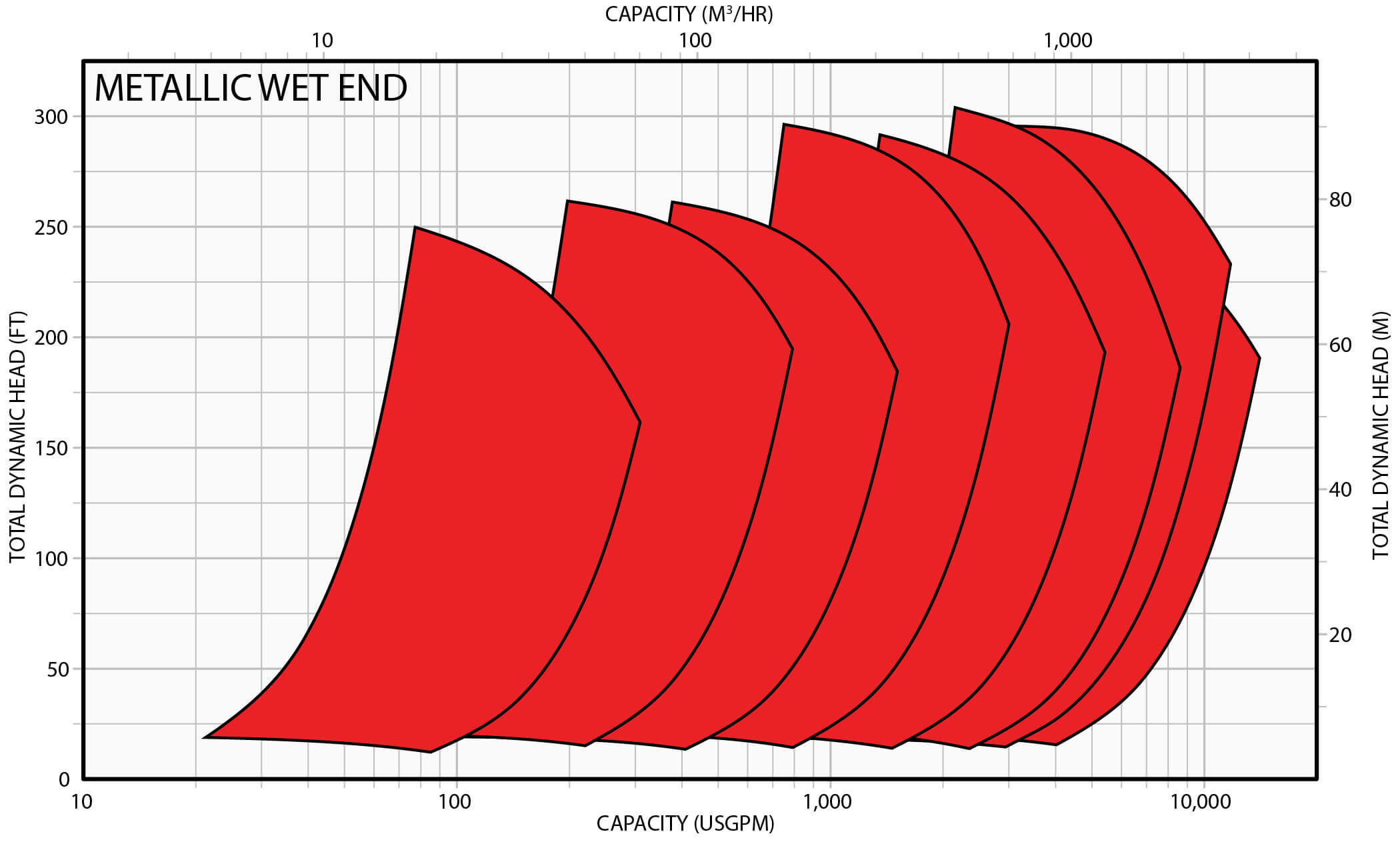

Range Capacities For Metal

EMW 50

2x2

EMW 75

3x3

EMW 100

4x3

EMW 150

6x4

EMW 200

8x6

EMW 250

10x8

EMW 300

12x10

EMW 350

14x12

Precision Engineering, Proven Reliability

The EMWs on the right pump Gypsum Slurry to a tailing pond in a Phosphoric Acid plant Mexico. The pumps exceeded customer’s expectations with its wear part longevity and pump performance.

Contact Wilfley for detailed specs, case studies, pricing, and customized solutions along with answers to all your questions. We are here to help you have the best options for your unique situation and operating budget.