S3 ACID SLURRY PUMP

Chemical-Acid Slurry Pump

The S3 pump was designed specifically for severe applications that are both corrosive and abrasive where an ANSI/ASME B73.1 is not enough.

Main Benefits

- It does not require water for seals

- Heavy-Duty design specifically design for acid slurries

- High durability

Main Applications

- Mining and mineral processing

- Phosphoric acid

- Acid slurry applications

Key Characteristics

Capacities:

Flows up to 2,500 gpm (568 m3/hr)

Heads:

Head up to 312 ft (95 m)

Max Working Pressure:

250 Psig (20 Bar)

Max Temperature:

250 °F (120°C)

Discharge Sizes:

From 2″ (50 mm) to 6″ (152 mm)

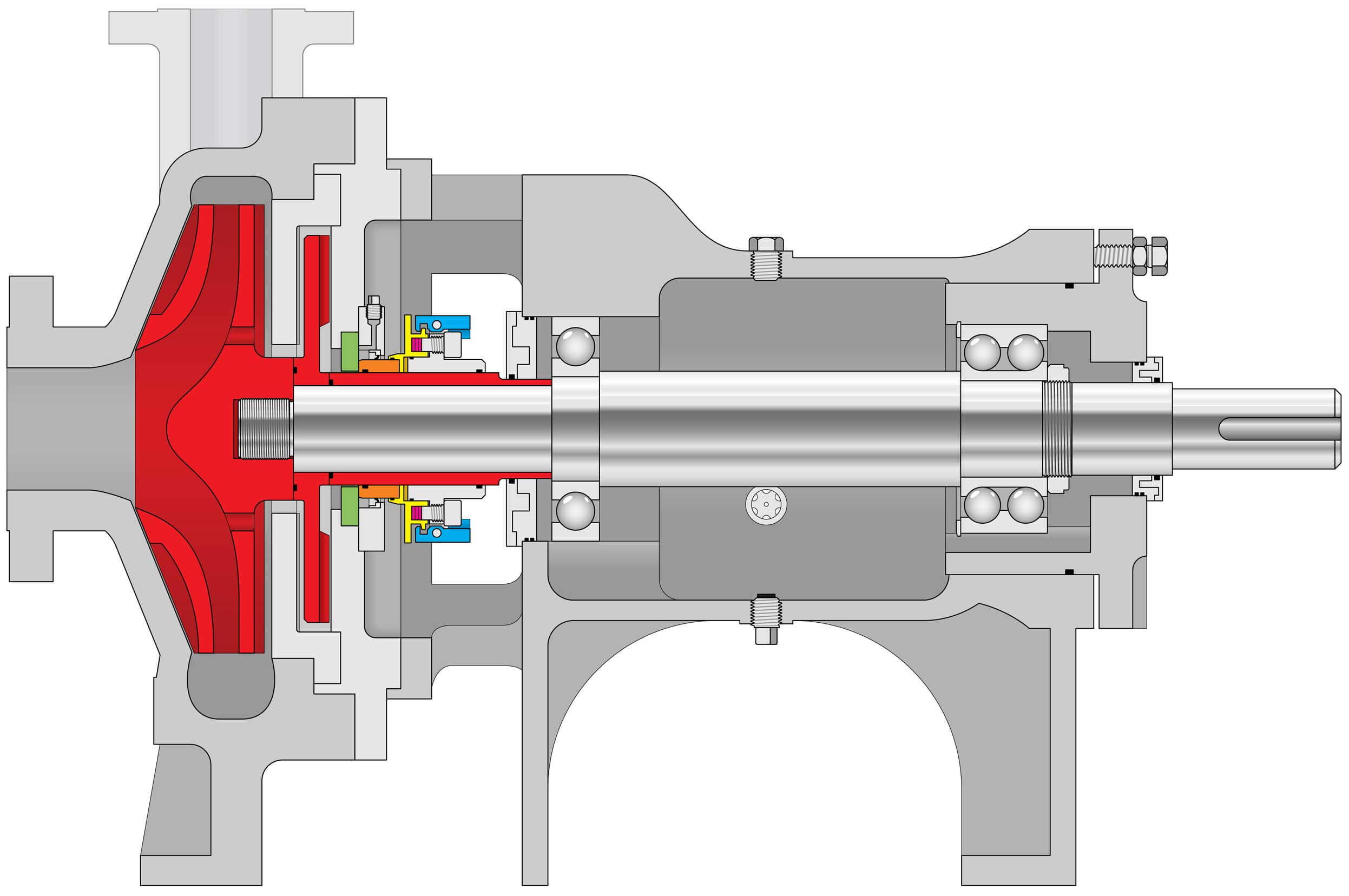

Tangential discharge

reduces wear

Front and rear impeller vanes

reduces wear

Extra heavy wall thickness extends wear life

(1/4” corrosion allowance vs. 1/8” with standard ANSI/ASME)

Heavy duty enclosed impeller

promotes high hydraulic eciency and reduced casing wear

Pressure / temperature

balance holes

The Wiley Waterless Sealt technology

is the combination of Expeller and Solidlock

Robust shaft with low L3/D4 ratios

minimizes deections and increases reliability

Easy clearance adjustment

to maintain efficiency and optimize hydraulic and/or expeller performance

Waterless Sealing: Wilfley’s Technological Advantage

The proven engineering based on Wilfley’s dynamic waterless sealing is trusted by many companies all over the world.

Materials Options

- Maxalloy 5A

- Maxalloy 5

- WCD4

Seal Options

- Wilfley Waterless Seal Technology

- Mechanical Seal

- SolidLock

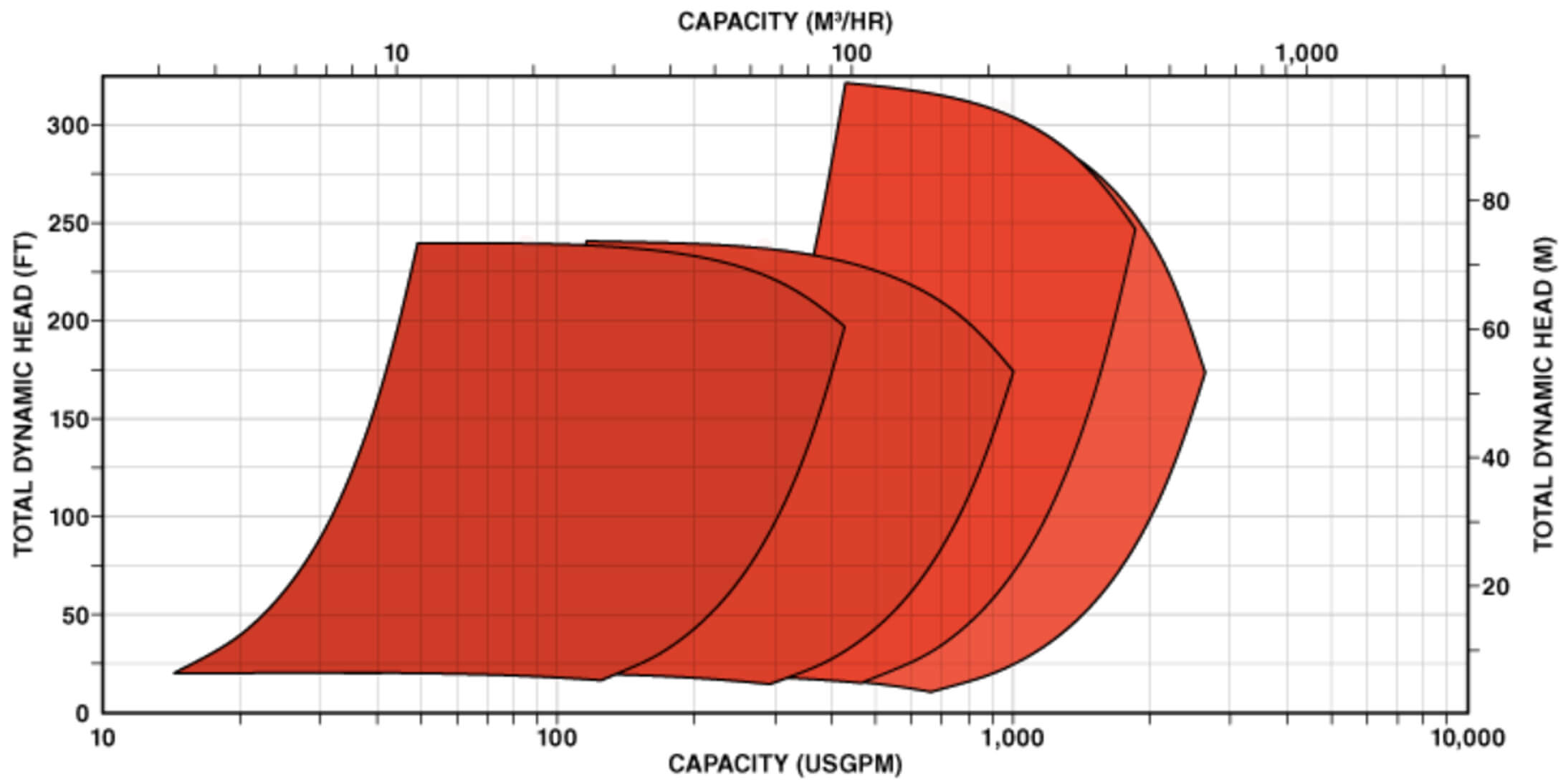

S3 Slurry Pump Performance Range Capacities

Flows up to 7,100 usgpm (1,613 m3/h)

Heads up to 735 ft (224 m)

S3

3x2-11

S3

4x3-11

S3

6x4-16

S3

6x6-16

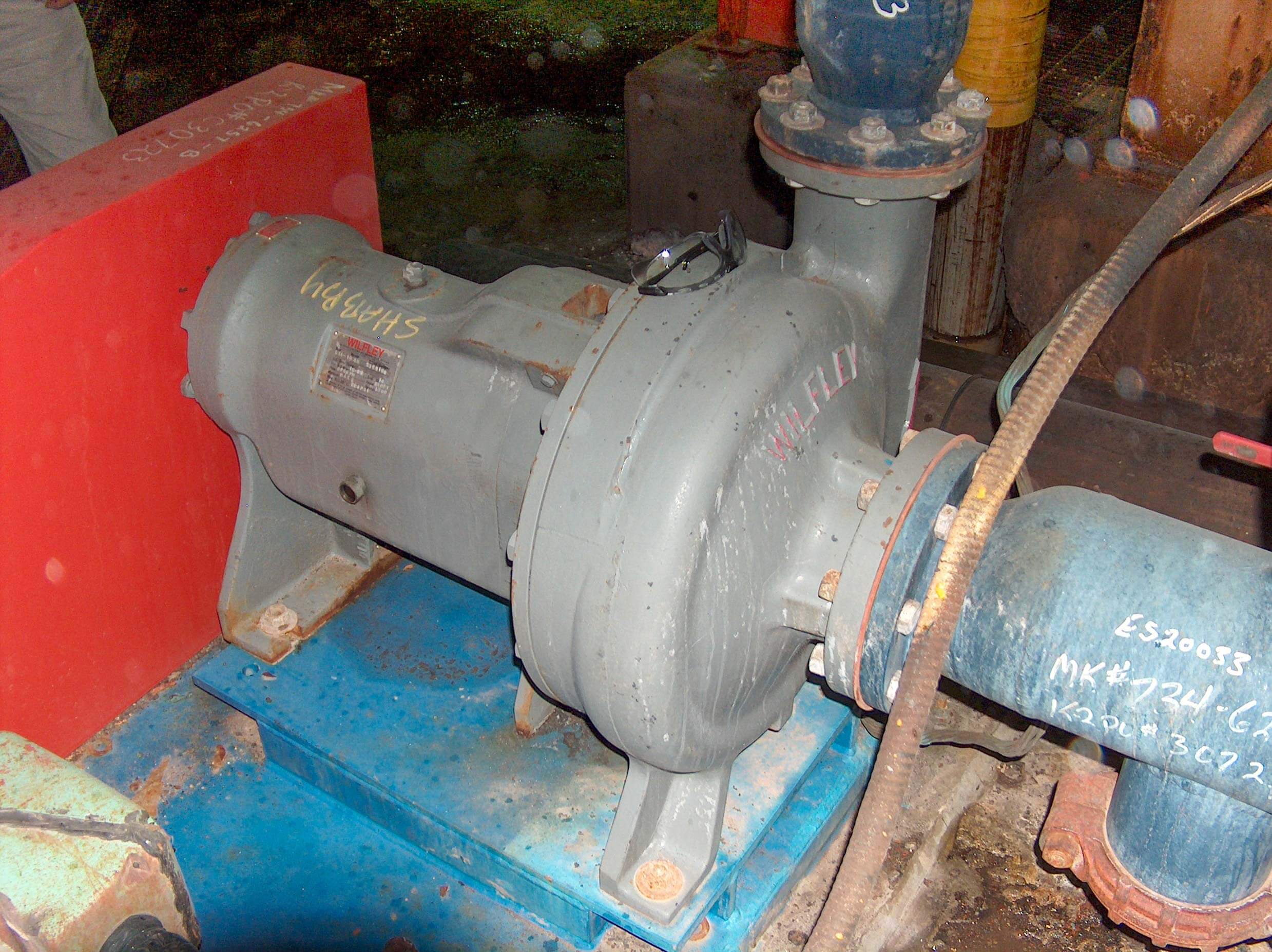

Precision Engineering, Proven Reliability

The robust design of the Model S3 pump coupled with The Wilfley Waterless and Leakless Seal Technology have proven to extend service life in Canada’s demanding potash applications. Conventional packing and traditional pump designs failed to offer extended service life due to slurry concentration and occasional dry running conditions. Wilfley’s dynamic seal eliminates the need for gland related work orders and seal headaches to keep operations and maintenance focused on other aspects of potash production.

Contact Wilfley for detailed specs, case studies, pricing and customized solutions along with answers to all your questions. We are here to help and want you to have the best options for your unique situation and operating budget.