AG DYNAMIC SEALED PUMPS BECAME A GREAT PLAYER IN ZINC PLATE PRODUCTION

Customer: :

Met Mex Peñoles – Torreon, Coahuila

Market:

Mining

Application:

Zinc Smelting from Ore

Country:

Mexico

BACKGROUND

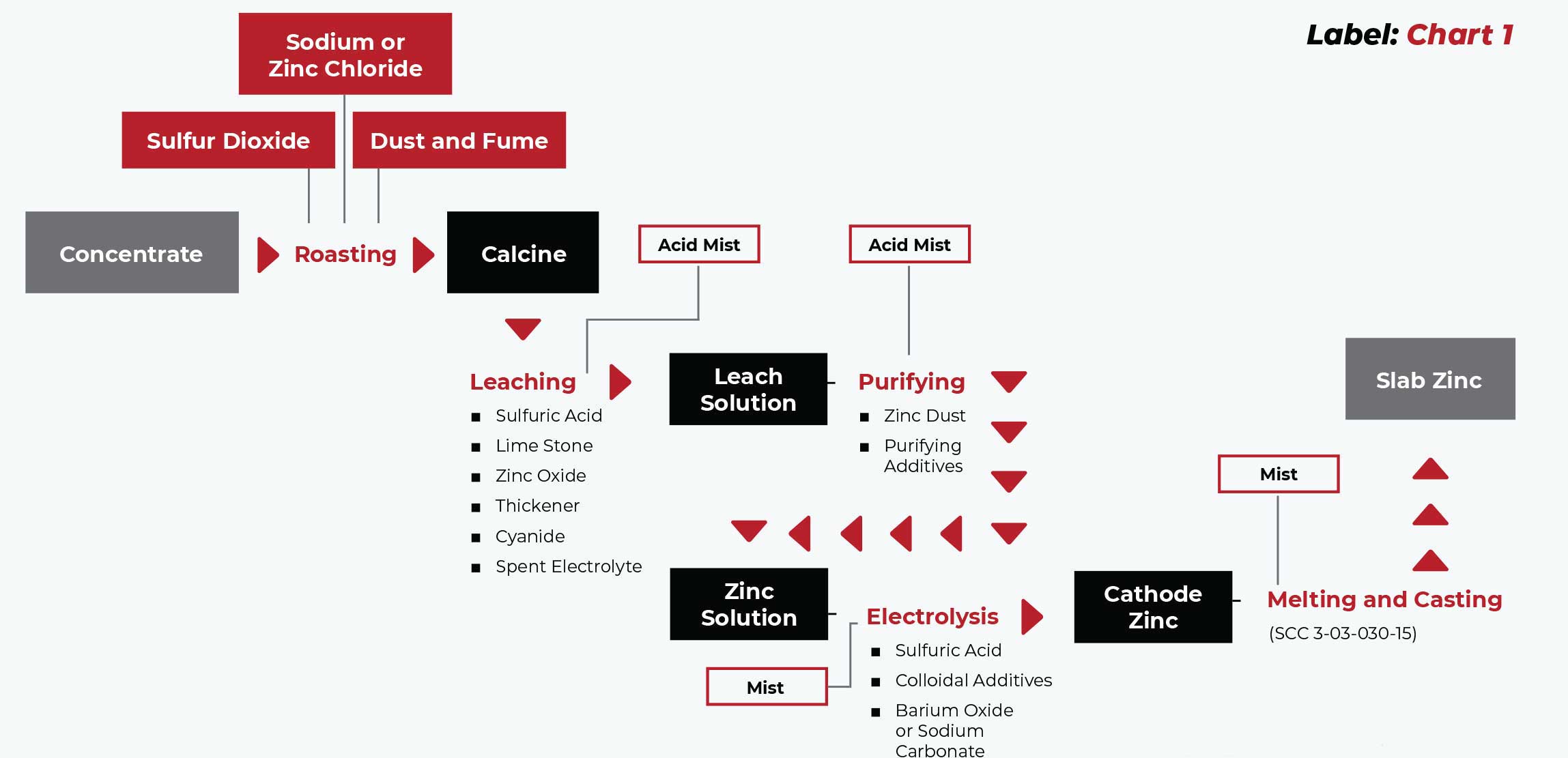

Zinc smelting is the process of converting zinc concentrates (ores that contain zinc) into pure zinc. It has historically been more difficult than the smelting of other metals, e.g. iron, because in contrast, zinc has a low boiling point. At temperatures typically used for smelting metals, zinc is a gas that will escape from a furnace, unless specific measures are taken to prevent it. Zinc is extracted from the purified zinc sulfate solution by electrowinning, which is a specialized form of electrolysis Roast-Leach-Electrowin (RLE).

Please see Chart 1 on Page 2

Sulfuric Acid plays an important role in the Zinc production (Leaching, Purifying, Electrolysis), Wilfley as Chemical pump manufacturer finds a niche on this application.

CHALLENGES

Customer used to have an extended list of applications with just one pump brand manufacturer. They were having continuous pump operational failures, lack of spares at site and continuous leakage from pump packings, which affected their process reliability. In 1996 customer allowed Wilfley to install his first AG Chemical Pump Dynamically Sealed. With Wilfley Metallurgy, able to handle solids and run dry without causing damage to the pump and zero leakage while running, the AG pump rapidly became a satisfactory success story at their facility.

THE SOLUTION

More than 20 Wilfley AG pumps replaced previous pump manufacturer increasing customer plant reliability.

THE RESULT

Wilfley became a confident customer partner on their spent acid applications for Zinc Plates production.

AG PUMP

The Wilfley AG pump first ANSI B73.1 developed in 1969, simple design plus Wilfley Alloy 20 Metallurgy one of many materials designed to handle highly corrosive applications.

And Wilfley Service for the life of the pump, selling complete units and spare parts for all our pumps.