Almost $60K on customer savings with Wilfley EMW Slurry Pump

Customer: :

Grupo Mexico – Buena Vista del Cobre

Market:

Mining

Application:

Molybdenum from Only Copper Concentrate

Country:

Mexico

BACKGROUND

Grupo Mexico is the largest mining corporation in Mexico and the third largest copper producer in the world. It has one of the largest copper reserves in Mexico and the world with 36 million tons. Its Buenavista del Cobre mine is in the north-west of Mexico, in a dry and desertic area, being the third largest copper mine in the world and Molybdenum is a subproduct from Copper extraction.

Only 0.005 to 0.05 is the molybdenum content on Copper, but it is 60% of global production as a by product from Copper and Tungsten.

CHALLENGES

Slurry pumps are required for Moly extraction which sent the slurry to filter press to remove all water and humidity possible. So, slurry specific gravity/ density is a key factor to maintain. If filter press receives too much water from pump packings (product dilution) a rupture from filter cloths can be observed. Once a filter cloth is broken, it requires about 6 hrs. labor to replace it and about US$15K per filter cloth.

Also, too much water coming out from packing area on the pumps creates premature bearing failures by contaminating oil or grease in pump bearing housing, plus makes an unsafe working place around the pumps, requiring cleaning actions (additional labor).

THE SOLUTION

Wilfley sold an EMW 75 (3×3) Slurry pump dynamically sealed and Solidlock State of the art Static Seal Waterless/Flush-less (no packings or mechanical seals).

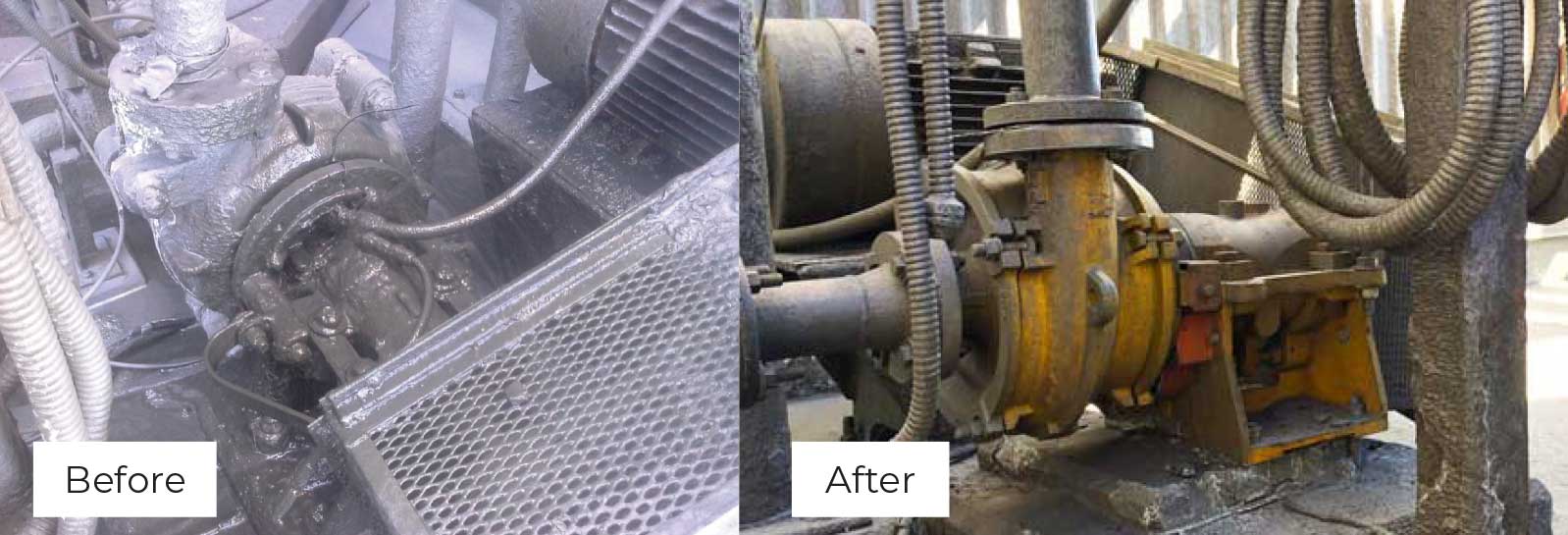

THE RESULT

After Wilfley pump was installed, customer observed two years filter press operation without replacing filter cloth. No leakage around the pump making clean and safe work environment. Total estimate saving for customer are $57K each time cloths breaks. Based on $8/Lbs (Molybdenum), plant production 10.5 ton/day, a plant stopped for 6h plus Filter Clots replacement cost ($15K).

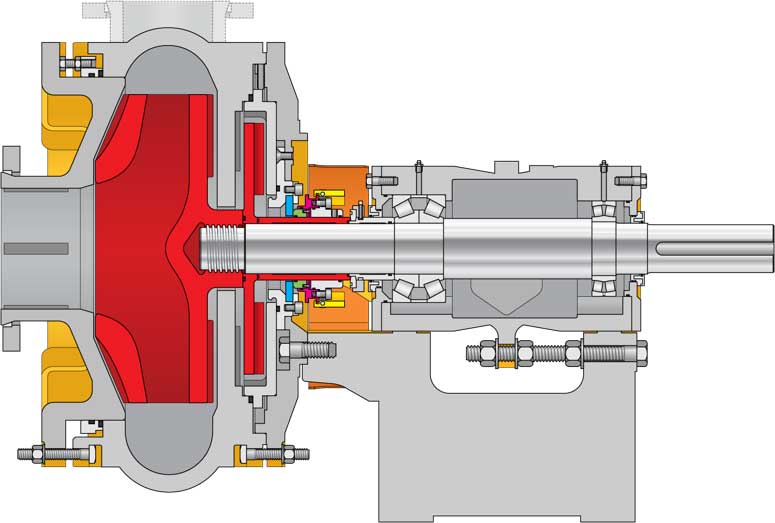

EMW Heavy Duty Slurry pump

The EMW Wilfley pump, Heavy Duty Class 3 and 4 Slurry pumps with Wilfley seal Technology, the Dynamic Seal while Running with no need of flushing (waterless) and Solidlock Static, no product dilution besides a repeatable reliable static seal with no leaks (leakless).

The Robust wet end construction of the EMW pump built to last and features components with double the thickness of comparable medium duty slurry pumps, combined with Wilfley’s proprietary Maxalloy 5A hard iron and elastomer liners, creates the ideal slurry pump for abrasive applications.

The EMW has 21st Century Hydraulics with latest computational fluid dynamics software to determine the optimal balance between hydraulic performance and wear life.