As discussed in the February article on Low Flow Concerns in Centrifugal Pumps, one of the motives for establishing a minimum continuous safe flow rate (commonly abbreviated as MCSF) is temperature rise in the fluid. There are several causes of efficiency losses in all centrifugal pumps and most of the wasted energy is converted into heat. That’s right; your pump could be used as a (albeit dangerous) heater.

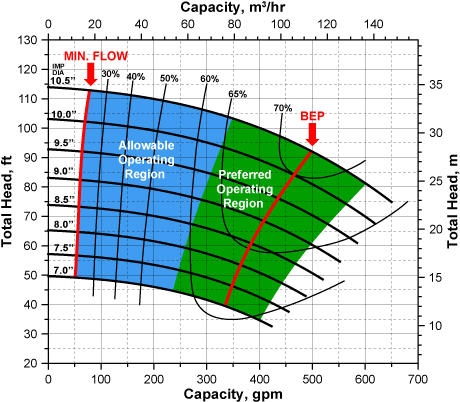

The performance chart above indicates the corresponding pump efficiency peaks around 70%. Ignoring the minor energy lost in the anti-friction bearings in the power frame, the other 30% of applied energy can be considered lost as heat. For water, the full diameter performance of 500 USgpm at 92 feet and 70% efficiency requires 16.6 hp (113.5 m3/hr, 28m = 12.4 kW). Unity efficiency would only require 11.6 hp (8.7 kW) – a difference of 5.0 hp (3.7 kW). Therefore in effect, you have a 3,700 watt heater. Fortunately, 4,170 lbs (1,891 kg) of fluid (room temperature water in this example) is moving thru the pump to remove that heat to a negligible 0.05°F (0.03°C).

The equation for determining this value is as shown below:

ΔT = H/ (778xCP)*(1/ƞ-1) for Imperial Units

ΔT = H/ (432xCP)*(1/ƞ-1) for Metric Units

Where:

H = Total developed head of the pump at the operating point, in feet (USCS) or meters (SI)

CP = Heat capacity of the fluid, in BTU/lb-°F (USCS) or cal/gm (SI)

N = Pump efficiency at the operating point in decimal form

Temperature Rise vs Flow for Water on a 4×3-10 Pump

These simplified equations do not account for heat dissipation through the pump parts, compressibility of the fluid and changing heat capacity of the fluid. However, it’s clear that low flow conditions can significantly increase the fluid temperature and should be avoided.