Wilfley Industrial Pumps Blog

Molybdenum from Only Copper Concentrate

Almost $60K on customer savings with Wilfley EMW Slurry Pump.

After Wilfley pump was installed, customer observed two years filter press operation without replacing filter cloth. No leakage around the pump making clean and safe work environment.

USA Ethanol Plant

Wilfley A9 Pump Keeps Running After 5 Years

There was so little wear, the customer re-assembled the pump and put it back in service for another year. The pump has been in service almost 5 years with virtually no maintenance required. The customer has since purchased a second Wilfley A9 pump.

Doré Plant

WCD4™ IMPROVES 400% WEAR LIFE

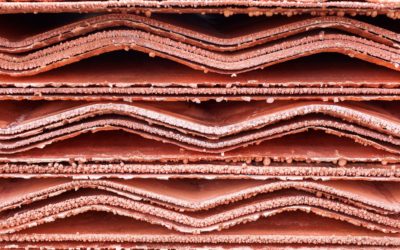

Codelco Chuquicamata is the largest open pit copper mine in the world, located in the north of Chile, just outside Calama. It began operations in 1952 and has copper reserves of 40 years.

Filter Feed Application

ONE WILFLEY EMW200 SAVES MORE THAN 500,000 GALLONS OF WATER IN ONE YEAR

Grupo Mexico is the largest mining corporation in Mexico and the third largest copper producer in the world. Its Buenavista del Cobre mine is located in the north-west of Mexico, in a dry and desertic area.

A.R. Wilfley – COVID-19 Plan

Colorado, USA, March 2020 A.R. Wilfley & Sons, Inc. will remain open to serve the customer no matter the circumstance until otherwise stipulated by government law. We assure our employees, customers, and vendors that our doors are still open and operating as usual,...

A9 Chemical Pump Extends Wear Life in Ethanol Plant

It’s a fact, any pump part that comes in contact with an abrasive slurry will inevitably wear out and need replacing. However, if your pump is currently wearing through parts at an obscene and unacceptable rate, it doesn’t mean it’s something you need to just accept...

Wilfley Solves Critical Problem in Copper Mine

One of the worst nightmares for a production manager is when a key piece of machinery fails and you’re forced stop production and lose critical time and money. Something as dreaded as this only needs to happen once to keep you up at night worrying until the root cause...

Wilfley Duplex Stainless Steel Superiority Proven in Phosphoric Acid Service

Material excellence has always been one of the pillars of Wilfley’s success, solidified by a restless focus on operational longevity and optimized value. By contrast, many suppliers focus intently on reducing cost without consideration to increasing value....

Wilfley WCD4™ Duplex Stainless Steel vs 904L Austenitic Stainless Steel

Basic Wear Mechanisms of Centrifugal Pumps Built in Stainless Steels Due to general pump design the solid particles in pump fluid have a small angle of impingement against the wet end components. Therefore, impacting wear has very little effect on the overall...

A9 Chemical Pumps Extend Mechanical Seal Life

The Model A9 heavy duty centrifugal pump is a proven design that provides extended mechanical seal life and maximum uptime and represents the culmination of nearly 90 years of continuous improvement in chemical process handling equipment. A modern descendant of the...

Do Dynamically Sealed Pumps Have Higher Operating Costs?

There is a common misconception in the pump industry that dynamically sealed pumps have higher operating costs due to the extra power required by the expeller. This may appear to be true if you only look at the electricity required to operate the pump but when you...

Leading 2016

As the dust settles and the path of product flow is completed upon our new floor, we turn as a team to more focus on what is next; where and how to inform ourselves to provide the platform for confident directives, determining...